Timeless

With nearly 100 years of experience.

Fuji-Haya Electric is the longest local manufacturer of electrical distribution

and control equipment in the Philippines

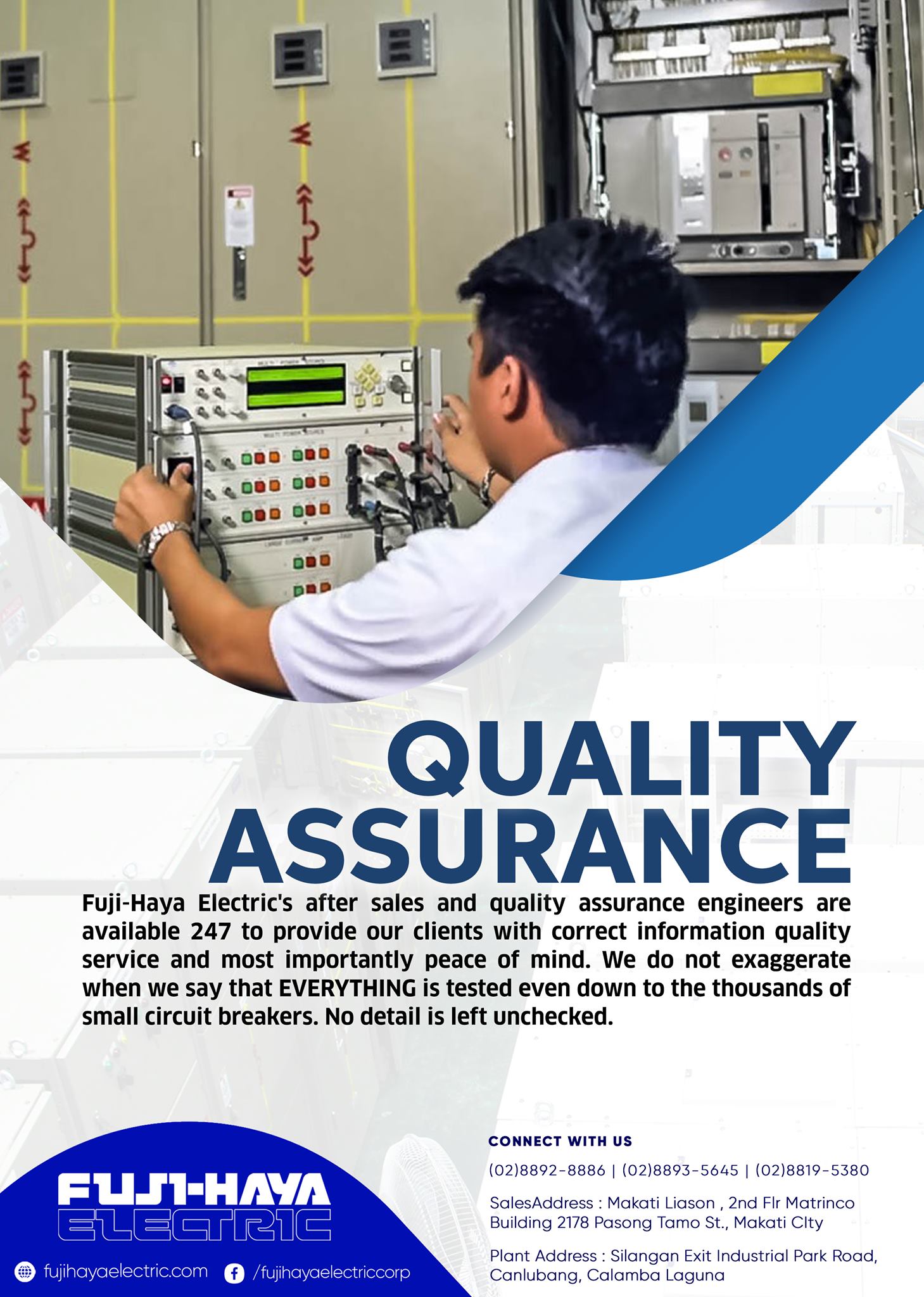

Quality

100% of the products that we make undergo rigorous quality testing and complies with local and international standards. Our engineers constantly work with our clients to achieve the best quality of electrical equipment that are safe for both property and personnel.

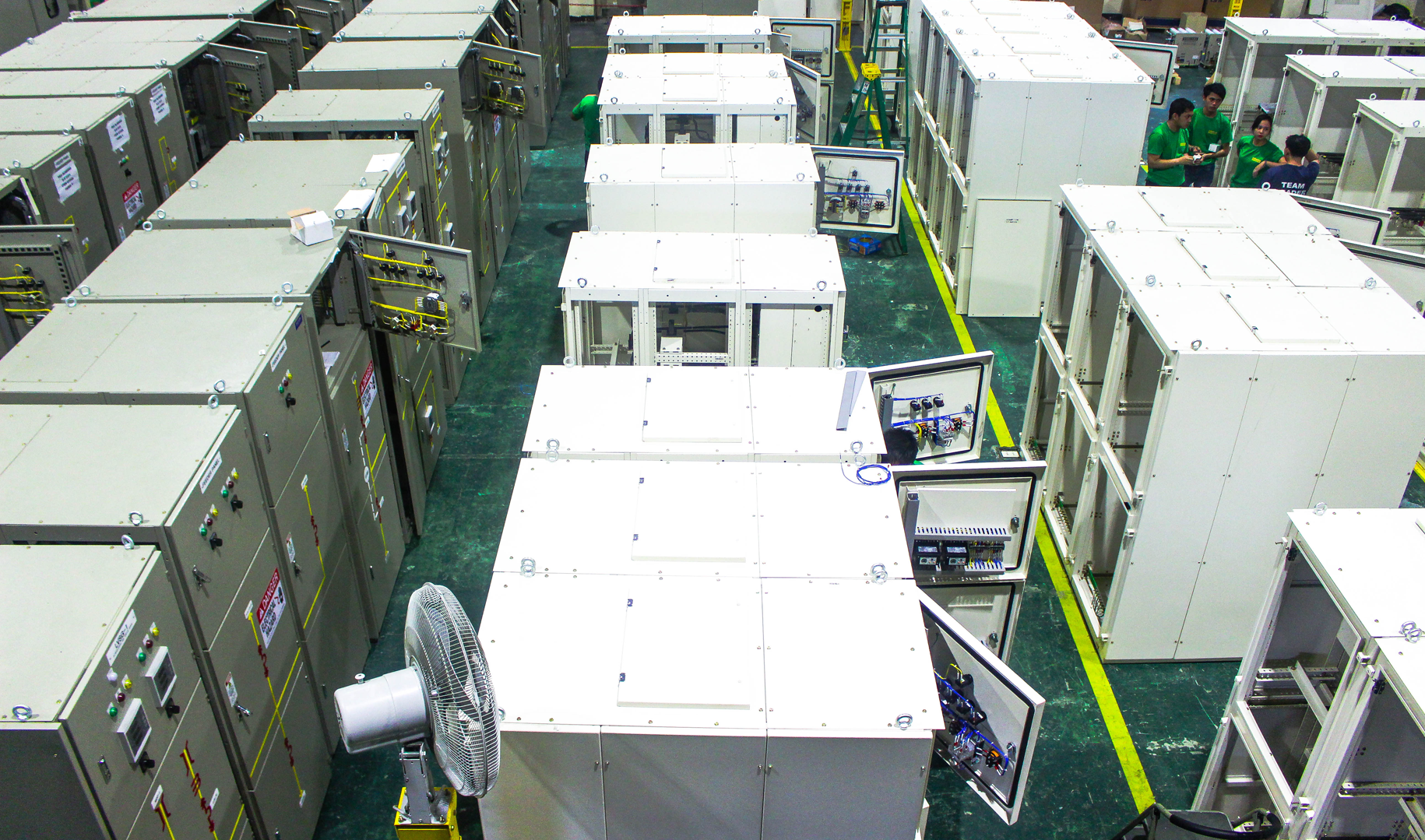

Capacity

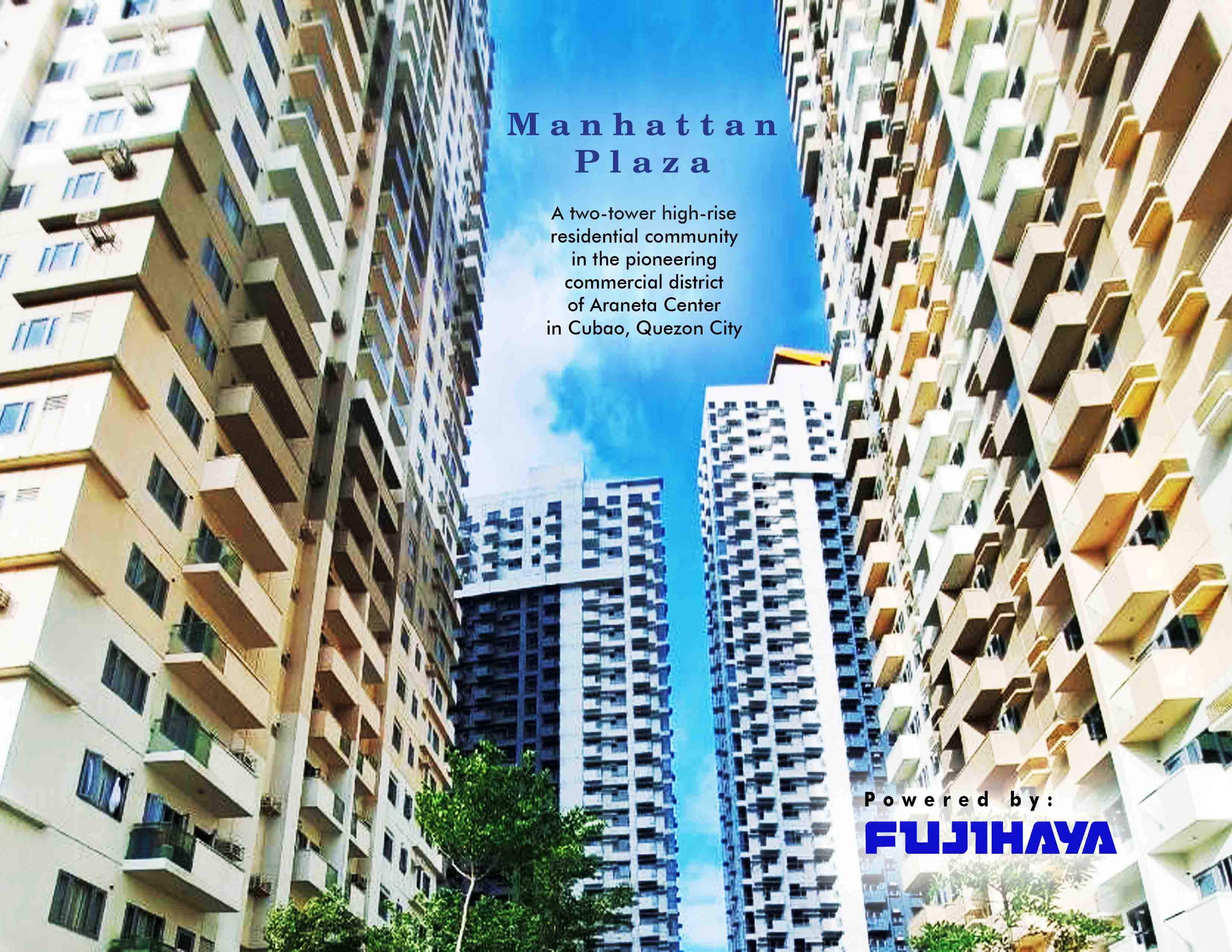

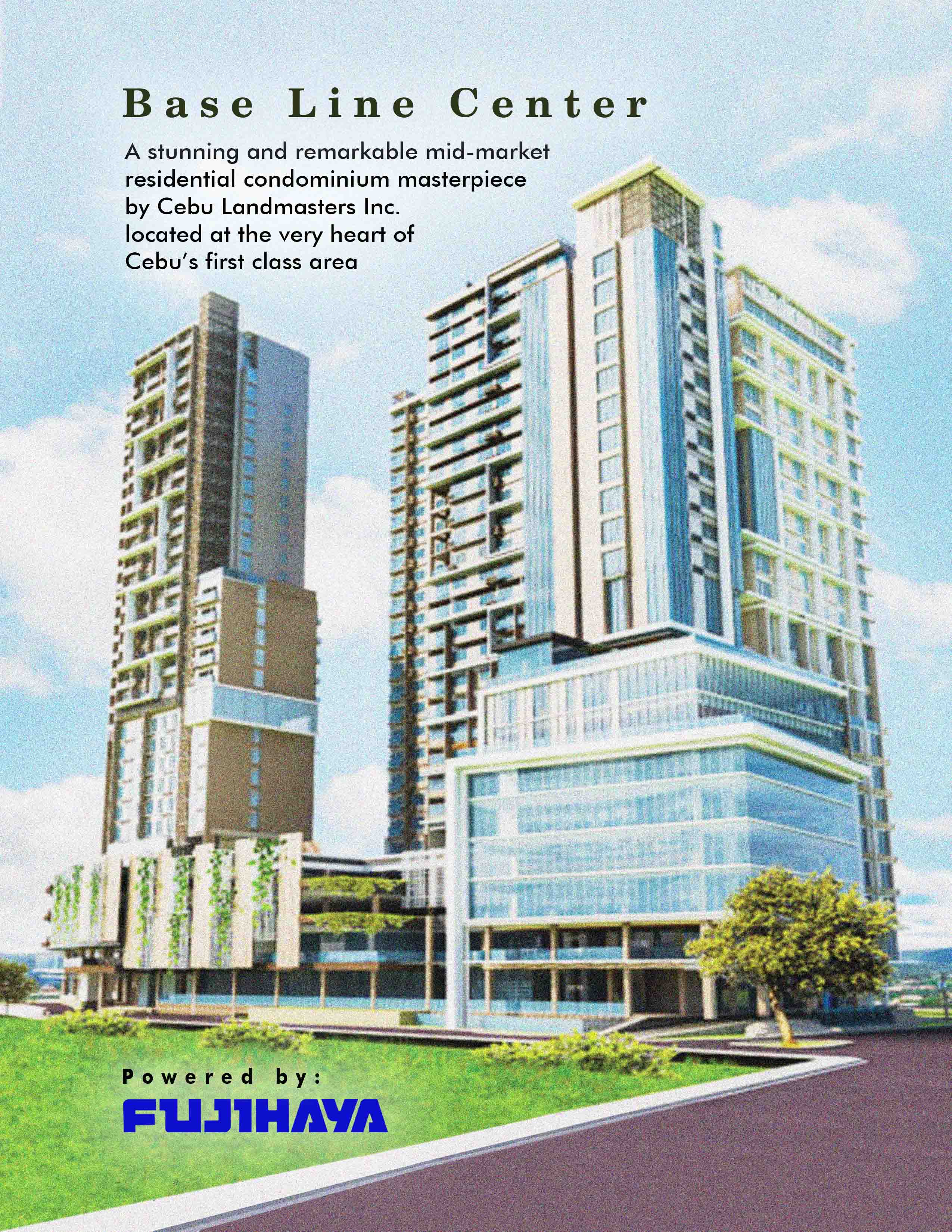

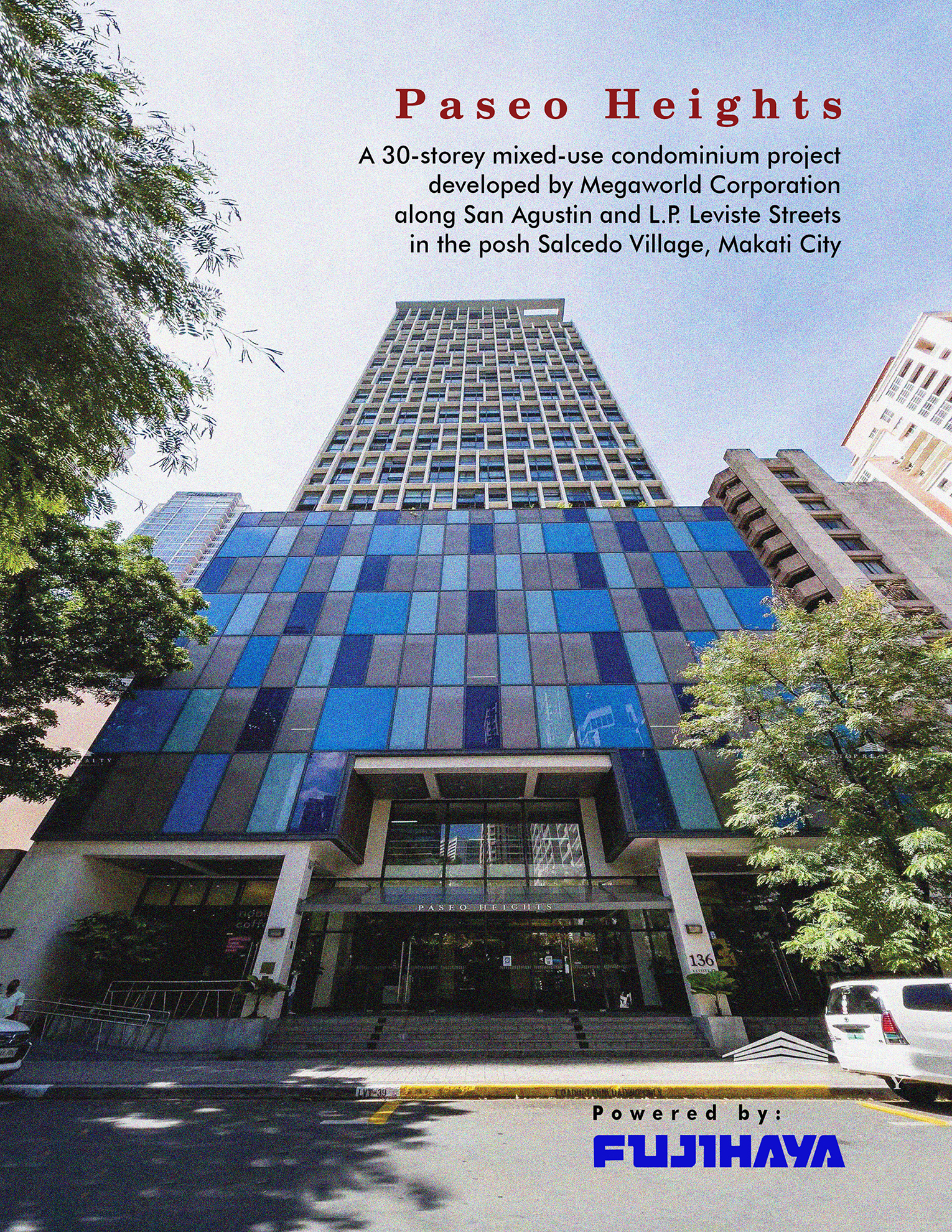

With the largest assembly bay the country together

with state of the art machinery, Fuji-Haya Electric

has enough capacity to service the entire Philippine Market.

Service

Fuji-Haya Electric engineers are available 24/7 to provide our clients with correct information, quality service, and most importantly, peace of mind.

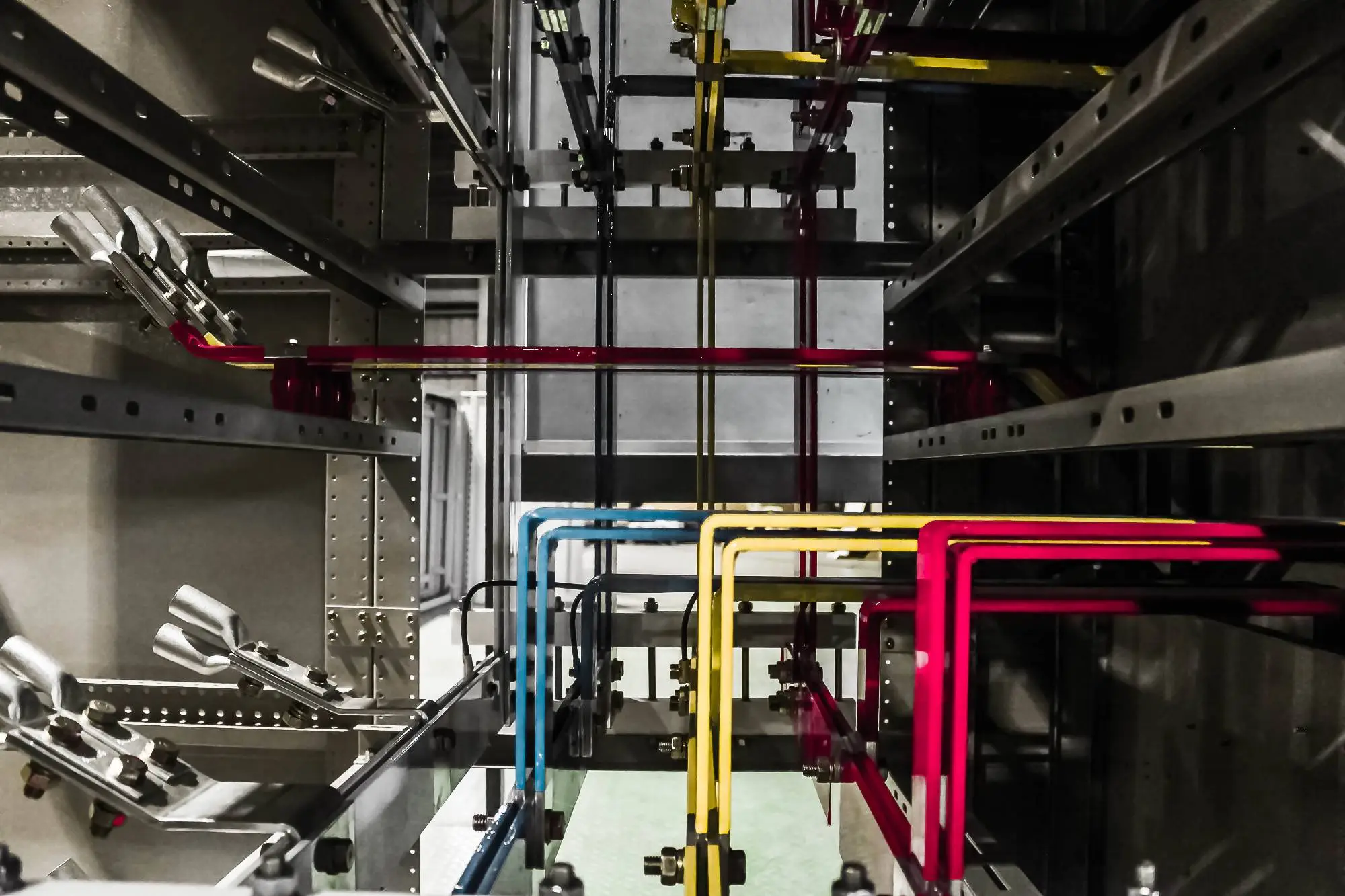

Products

From Unit Panelboards all the way up to Busduct,

Transformers, and 34.5 KV Switchgears, Fuji-Haya Electric has the complete product line to satisfy customer needs